6 mins to read

CESAR .

Publicado em: 21 de janeiro de 2026

How CESAR and Petrobras Turned Spare Parts into Predictive Intelligence With AI

About Petrobras:

Brazil’s state-controlled energy giant ranks among the world’s largest oil companies: No. 58 on Forbes Global 2000, No. 71 on Fortune Global 500. Headquartered in Rio de Janeiro, Petrobras produces approximately 2.8 million barrels of oil equivalent daily across a vast network of offshore platforms and onshore industrial plants—with millions of equipment items and parts tracked in its enterprise systems.

Industry Context:

Unplanned downtime costs offshore oil and gas organizations around the world an average of $38 million annually—with worst-case scenarios reaching $88 million per year (MaxGrip/Kimberlite). Across industrial sectors, downtime runs approximately $125,000 per hour (ABB Survey 2023).

Companies that shift from reactive to predictive maintenance see up to 36% reduction in unplanned downtime (MaxGrip/Kimberlite). Shell reported 40% fewer equipment failures after implementing AI-powered predictive systems (Tank Terminals/Energies Media).

In any industrial operation, the availability of spare parts means the difference between production continuity and crisis. A missing component can halt operations for days. Excess inventory ties up capital and warehouse space.

For Brazilian energy giant Petrobras, which manages millions of equipment items across offshore platforms and onshore plants, the stakes are enormous.

The company faced a common but costly challenge: scattered data, manual processes, and no reliable way to forecast which parts would be needed, when, or where. Errors in parts selection triggered a cascade of problems, including emergency purchases at premium prices, overburdened procurement teams, bloated or depleted inventories, and operational interruptions that rippled across the business.

Petrobras turned to CESAR to co-develop a solution: the Realistic Spare Parts Estimator (ERS) – an AI-powered system designed to predict spare parts demand with precision, cut costs, and transform maintenance management across global operations.

The Data Challenge: Millions of Parts, Zero Visibility

The core obstacle wasn’t technology; it was data. Petrobras had vast maintenance records stretching back to 2005, when the company implemented SAP. But that data sat fragmented across systems and organizational silos.

The numbers tell the story: millions of equipment items and parts registered in SAP, each generating maintenance records – consumption dates, part descriptions, equipment targets, and pricing. Yet accessing this information required navigating multiple SAP modules, with no unified view of actual spare parts needs.

The result: manual, time-intensive processes for gathering and verifying data. Increased error risk. Delayed decisions. And no methodology for forecasting future demand based on historical patterns.

The ERS Solution: Predictive Intelligence at Scale

The new ERS was engineered to solve this. The system processes large volumes of historical data through an innovative pipeline, generating accurate, realistic forecasts of spare parts needs tailored to the operational and environmental conditions of each Petrobras facility.

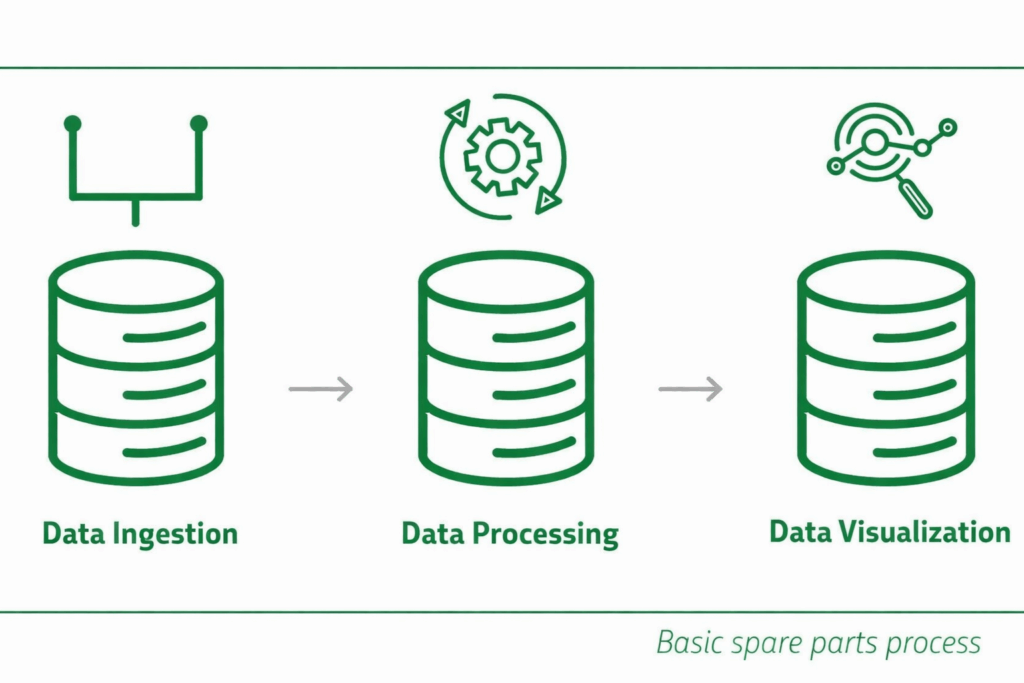

The platform integrates three core capabilities:

- Historical analysis with predictive modeling

- Real-time inventory monitoring and management

- Continuous tracking of equipment consumption patterns

Users define target periods and equipment models; the system calculates demand, lead times, unit costs, and total pricing.

Armed with these insights, Petrobras can select the optimal supply strategy for each scenario:

- Strategic inventory builds with optimized quantities and storage periods

- Comprehensive contracts with supplier-held inventory

- Additive manufacturing for hard-to-source components

- Off-the-shelf purchasing for high-availability items

Interactive dashboards and detailed reports provide complete visibility into parts utilization and efficiency – enabling data-driven decisions that were previously impossible.

“In a sector where accuracy and precision define success, anticipating possibilities is essential to eliminate the unexpected. Innovative solutions like ERS emerge when there is collective inspiration—where each team member is motivated to transform what previously seemed impossible into practical routine for decision-makers.” — Douglas Azevedo, Tech Leader, CESAR

Two Patented Methods, One Integrated Platform

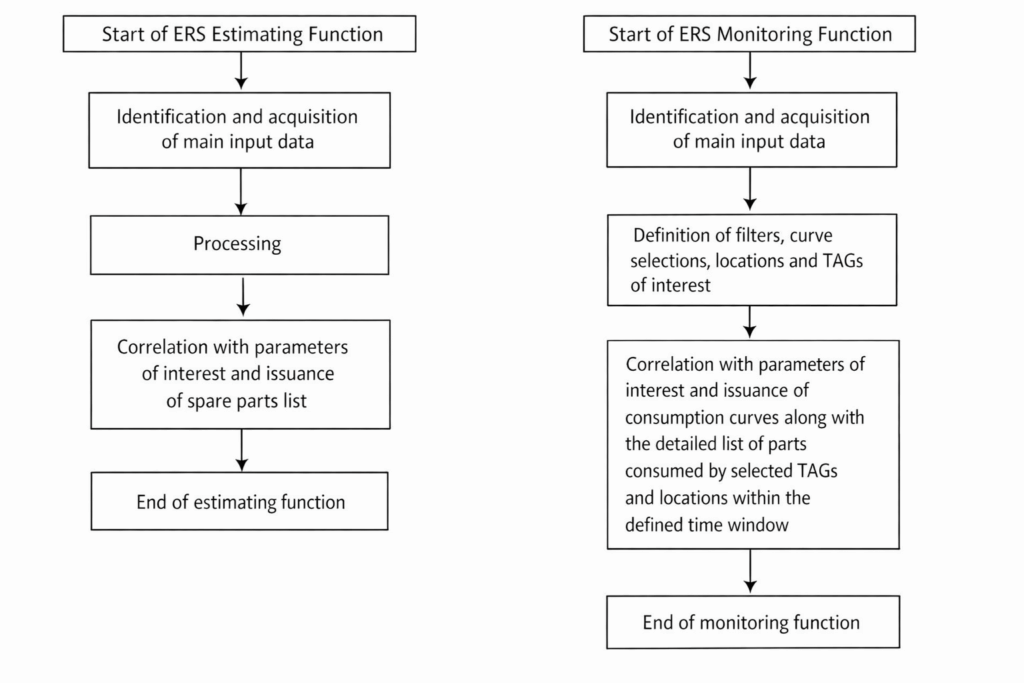

ERS is built on two methodologies patented by Petrobras: an Estimator Function for forecasting demand and a Monitoring Function for tracking consumption patterns in real time.

Identify and acquire primary input data → Process data → Correlate with parameters of interest → Generate spare parts list.

Identify and acquire primary input data → Define filters, curves, locations, and equipment TAGs → Correlate parameters and generate consumption curves with detailed parts lists by TAG and location within defined time windows

ERS development followed an iterative, design-driven process using agile methodologies. CESAR and Petrobras teams worked closely with end users throughout the initiative to collect feedback, make rapid adjustments, and ensure the new platform proved practical in its operating environment.

The Cultural Shift: Trusting the Algorithm

This project is part of Petrobras’s broader digital transformation efforts to replace slow, expensive, imprecise processes with faster, more accurate, data-driven operations.

But technology alone doesn’t drive change. Adoption does.

The most challenging phase came after solution delivery: convincing users to trust the system and integrate it into daily workflows. Trusting software’s decision-making represents a significant paradigm shift. In any context, this digital transition becomes a cultural revolution. People tend to distrust automated decisions—especially when algorithms demonstrate greater agility and accuracy than traditional methods.

Agile practices including daily stand-ups, biweekly planning, retrospectives and showcases have been embedded since the internal startup phase in 2022, when the first prototype launched. This collaborative rhythm continues to drive adoption.

“It’s a very close cooperative relationship, where many decisions, adjustments, and guidelines are being made all the time. The relationship with CESAR is very effective, especially in terms of quick decision-making and high-quality deliverables.” — Vinícius Zimmermann Silva, DSc, Product Owner, Petrobras

Seven Years In: Measurable Impact across 57 Business Units

This project has been running since 2018 – delivering seven years of persistence, iteration, and refinement. Today, ERS is actively used across 57 Petrobras management areas, with adoption expanding as results compound.

The operational impact:

- Decision time collapsed: Spare parts inquiries that took weeks or months now resolve in seconds

- Proven scalability: ERS’ success led to expansion for strategic spare parts forecasting on Búzios field platforms

- Smarter procurement: Accurate forecasts enable informed purchasing, avoiding emergency acquisitions at premium prices

- Eliminated last-minute scrambles: Predictive planning reduces or eliminates expensive, delay-prone rush orders

“The Realistic Spare Parts Estimator (ERS) has the potential to transform how equipment spare parts management resources are handled, improving efficiency and reducing costs.” — Vinícius Zimmermann Silva, DSc, Product Owner, Petrobras

Ready to Transform Your Spare Parts Strategy?

Industries worldwide face the same challenges: fragmented data, ineffective forecasting, legacy system constraints, and operational inefficiency. Digital transformation offers a path to smarter, more efficient asset management—cutting costs while increasing reliability.

CESAR brings deep expertise in technology and innovation to this transformation. We partner with organizations ready to solve critical operational problems and redefine what’s possible: from research and ideation, to design and development, to testing and validated deployment. We deliver results. Explore CESAR’s Energy Sector Solutions →

Image credits: Petrobras Archive — Andre Motta de Souza

You may also like

Boardtec: Automação do controle de paradas para migrar de registro manual a realtime

CBA: Transformando dados em sustentabilidade com monitoramento do solo em Manaus

UCB Power: Da inspeção manual à inspeção inteligente com visão computacional