With 300+ wells to be explored across its vast deep-sea reserves on its five-year roadmap – each costing from $70 million to $100 million – Brazil’s Petrobras runs hundreds of complex reservoir simulations daily using high performance computers to reduce uncertainty and make better decisions.

If you research a list of the top-500 high performance computing (HPC) machines in the world – the ones that are the greenest (consuming less costly energy) and the most powerful – you’ll find that academic institutes and the largest energy companies such as Brazil’s Petrobras are some of the heaviest users of massive workloads.

Reservoir simulation is one of the most important calculations an oil and gas company can do, according to Rob Farber, an AI/HPC pioneer and global technology leader. The energy industry has been running “heroic simulation sizes”; requiring major industry players to progress to faster, more efficient simulations.

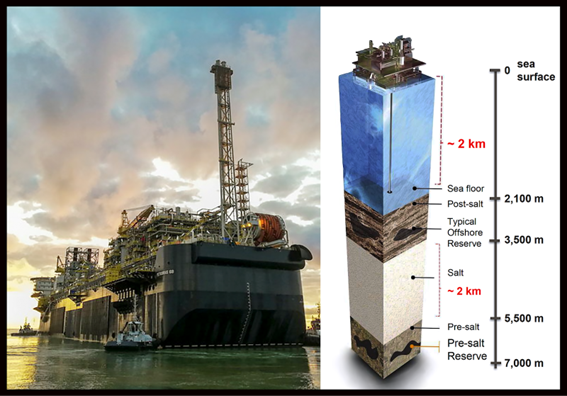

Oil and gas exploration and production is the core business of Brazil’s Petrobras, the largest public company in Latin America with a market capitalization of nearly USD $109 billion. The multinational energy corporation is a global reference in ultra-deep water exploration, and each deep-water well typically costs between $70 million and $100 million to explore and tap.

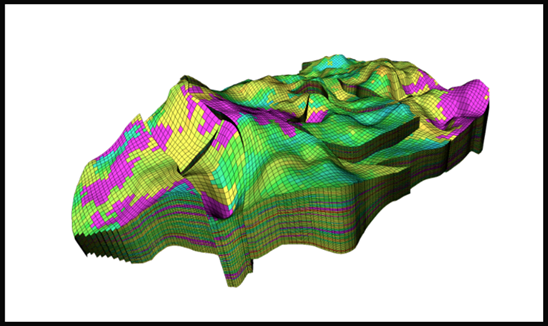

Petrobras plans to drill more than 300 offshore oil and gas wells during the next five years – a majority of them located far below the ocean’s surface between 2,100 meters and 7,000 meters or more. They’re oftentimes wedged within a complex topology below the seafloor in post-salt and pre-salt reserves. Exploring these reservoirs to make the best decisions requires simulating complex 3D computing models by using huge HPC infrastructures.

In order to understand and strategize the most efficient and lucrative approaches to production, Petrobras relies on its reservoir engineering team, spread across Brazil, who typically run hundreds of HPC simulations per day, to better predict how the oil and gas supplies deep beneath the sea will be explored. These engineers need to find which locations might be best to drill through the rock, what type of extraction strategy should be employed, which operational controls should be used to maximize the operations, and to predict the recovery volumes and cash flow, among other challenges.

First Year of Blue Sky Project Generates Great Results

In April 2023, Petrobras teamed up with an HPC engineering team at CESAR for what it calls a “blue sky” RD&I project – using a creative approach that goes beyond conventional thinking – to explore how new, accelerating superchip platforms could help speed up reservoir simulations to optimize its engineers’ precious time, and use far less power to reduce its carbon footprint.

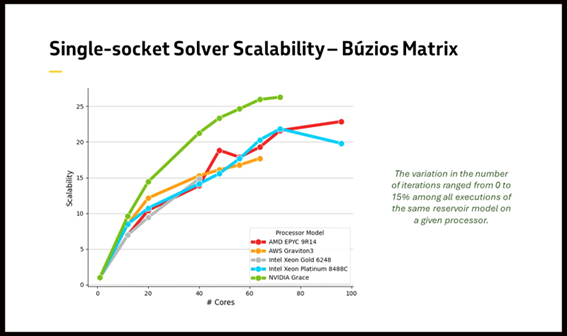

With the recent advances in ARM CPU processors, including the recently launched NVIDIA Grace CPU, CESAR and Petrobras set out on phase-one of the RD&I project to update the code of the most computationally expensive kernel of reservoir simulation to run on ARM CPUs’ high-performance and power efficient cores. The referred numeric kernel is the linear solver, which is implemented by the SolverBR and takes about 50 to 60 percent of the time in the process of a reservoir simulation.

“It is a massive challenge to do a conversion from one architecture to another. Many codes over the years have been very fine-tuned to run across entire architectures, and removing or rolling back software code is complex and time-consuming,” said Felipe Portella, IT Advisor at Petrobras who is the technical project leader. “We chose CESAR to partner with us because we had worked with them in the past with great success for other UX and generative AI RD&I projects.”

For the Solver BR port to ARM, the months of work to research, design, re-code and test the new ARM vs. traditional x86 chip architectures have paid off with significant accelerations to produce the complex simulations used by Petrobras’ reservoir engineers on a daily cadence. The RD&I collaboration has dramatically reduced the amount of processing time, while saving energy thanks to a new industry-leading generation of chips that enable up to 2X the performance of today’s leading servers on the market.

A rise in societal concern about high performance computing’s impact on the environment, corresponding increases in energy demand, and a trend towards reducing carbon emissions has led to an industry-wide movement to innovate new ways to run complex HPC simulations requiring large workloads more efficiently, at scale, while reducing energy consumption.

The Challenge Ahead: Convert the Full Simulator to Next-Gen HPC

“Now that we have a proof of concept and very solid results proving it’s quite worthwhile to port the code for the rest of the HPC simulator. We have already conquered the most time-intensive portion of this journey through the SolverBR,” said Portella. “In the months ahead, we will be working closely with CESAR and NVIDIA to redesign and deploy new code for the full simulator.”

Another type of simulator focuses on geo-mechanical issues of existing reservoirs to diagnose or prevent issues such as too much pressure that might cause a risk of oil leakage into the ocean. It’s a smaller code base than the reservoir simulator, and therefore a good candidate to be the next full simulator ported. Because it also supports a vital process in Petrobras to gain advance notice to avoid problems before they become more disruptive or expensive in the future, its importance as the next ARM full simulation increases.

“One of our intensive HPC engineering processes is to adjust those reservoir simulations to the historical data so we can better predict the future,” said Portella. “We even have a 3D visualization facility that lets our engineers wear VR glasses and walk into those virtual reservoir representations analyzing and exploring different data.”

This type of advanced tech RD&I for faster, more energy-efficient workloads to create HPC simulations from massive amounts of data is needed in other industry sectors, including finance, electric energy, drug design, space research, urban planning, and weather prediction. If you’re seeking to push beyond the current boundaries of innovation, consider contacting CESAR to help.

###

CESAR Innovation Center in Recife, Brazil (Porto Digital) is one of Latin America’s most renowned institutions for world-class research, design, and innovation on demand. For more than 25 years, CESAR has been a trusted partner for some of the best-known global brands seeking to co-develop breakthrough innovations that up-level their competitiveness and productivity.

If your organization needs expert research, design, and innovation support, please contact CESAR about tapping into hundreds of AI experts, architects, coders, designers, innovation managers, researchers, UX experts, and other advanced technology aficionados, please contact us here.